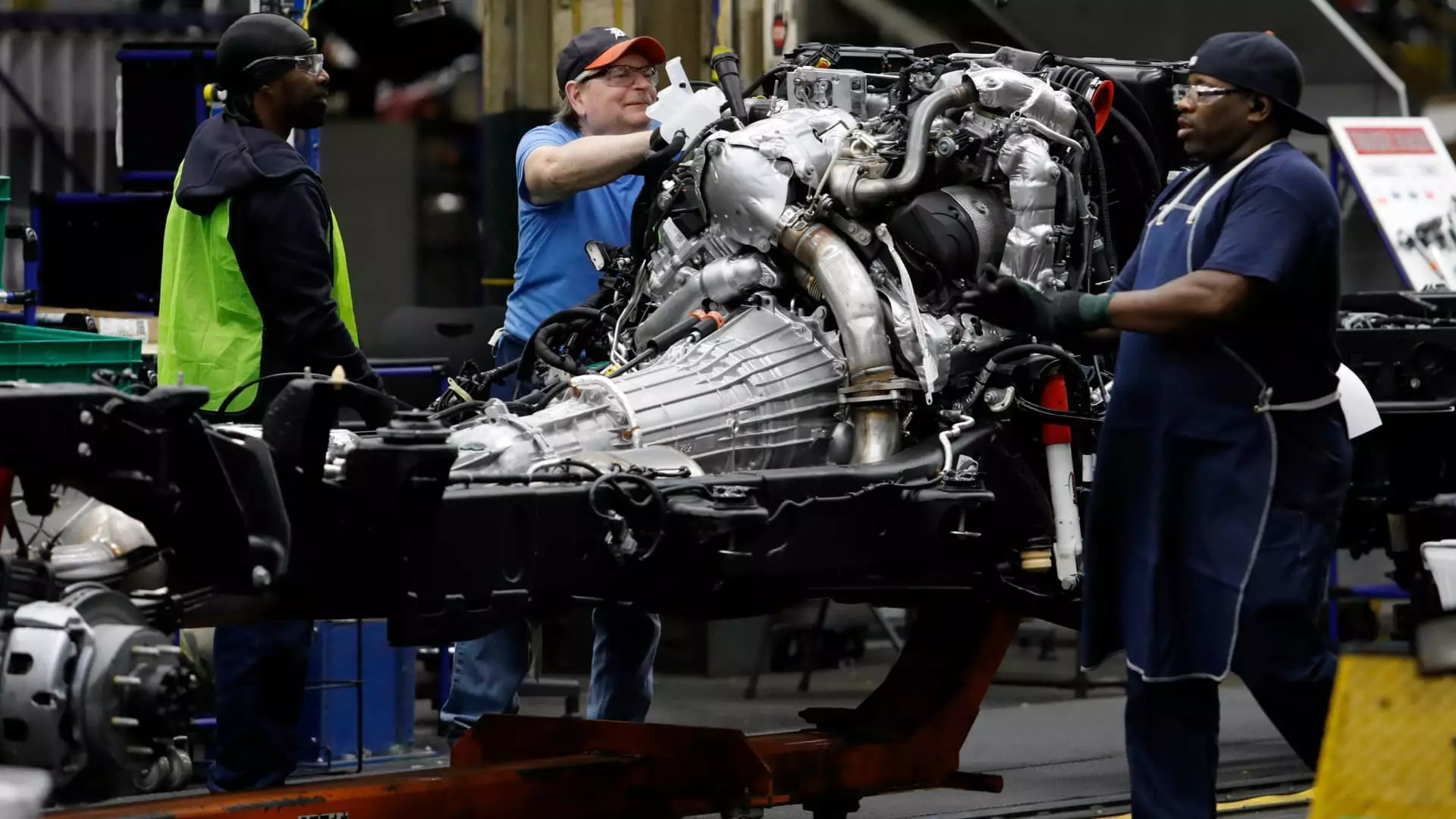

In a significant move reflective of the vulnerabilities faced by manufacturers, General Motors (GM) has announced the temporary shutdown of production at two of its key U.S. facilities. This decision is a direct consequence of supply chain disruptions caused by Hurricane Helene, which recently impacted various regions in the southeastern United States. Notably, GM halted operations at its Flint, Michigan plant, known for assembling heavy-duty trucks, alongside the Arlington Assembly in Texas, which is responsible for producing full-size SUVs, including popular models like the Chevrolet Tahoe and Cadillac Escalade.

Hurricane Helene’s trajectory led it to make landfall in Florida, wreaking havoc across multiple states and contributing to a tragic loss of life, with over 215 casualties reported. This natural disaster underscores the precariousness of supply chains, particularly in sectors dependent on a network of suppliers. While GM has refrained from naming specific suppliers affected, the company’s decision to halt production highlights how weather-related events can ripple through the automotive industry, forcing manufacturers to adapt quickly.

In light of the disruption, GM is actively engaging with its suppliers to facilitate a swift return to normal operations. A company representative remained non-committal about the exact timeline for resuming production, reflecting the uncertainty that often accompanies such natural calamities. However, they indicated that efforts were underway to mitigate the impacts on both workers and the broader community, emphasizing the automaker’s commitment to not only its workforce but also the supply chain ecosystem it relies upon.

Jeffrey Morrison, GM’s vice president of global purchasing and supply chain, elaborated on how the disruptions during the COVID-19 pandemic have altered the company’s approach to supply chain management. He noted that the pandemic prompted a thorough analysis of GM’s supply chains, leading to a more meticulous understanding and mapping of sub-tier suppliers. The greater visibility achieved in recent years is intended to better prepare GM for unforeseen challenges, such as hurricanes or labor strikes, ensuring a more resilient operational framework.

Despite the challenges presented by Hurricane Helene and the recent dock workers’ strike, GM remains focused on recovering from the disruptions. Company representatives acknowledged the learning curve brought by these events, shedding light on an evolving strategy aimed at reinforcing supply chain fortitude. Going forward, GM’s initiative to support its suppliers during production interruptions signifies a broader trend towards collaboration in the automotive arena, emphasizing shared responsibility and collective resilience in facing the uncertainties ahead.

The temporary production shut-down at GM illustrates the multifaceted challenges faced by the modern automotive industry. As natural disasters and other disruptions threaten the delicate balance of supply chains, companies like GM are prompted to adapt, strategize, and ultimately emerge stronger. By enhancing their understanding of their supply chain and working cooperatively with suppliers, automotive manufacturers are better positioned to navigate future uncertainties and sustain their critical production capacities.